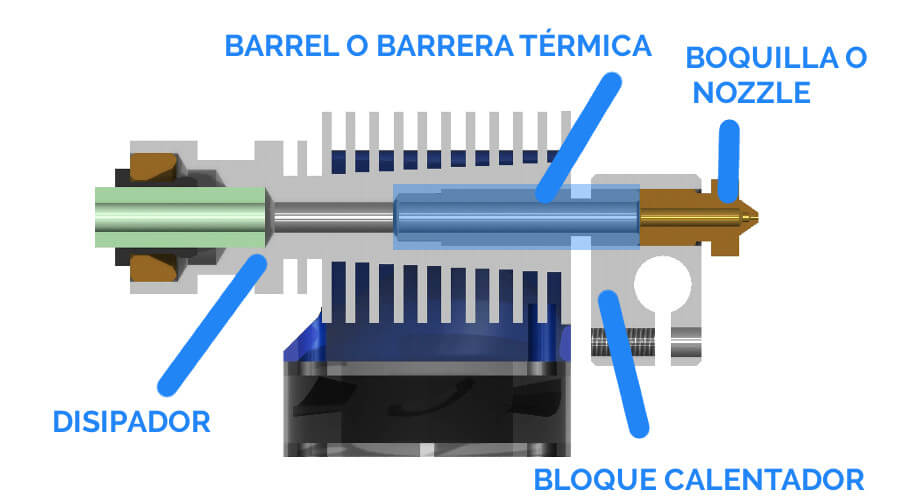

Today we will begin our article talking about an essential component in all our printers called nozzle.

Inside our nozzle is where the melting of our filaments is carried out and the point of extraction of the same, to then be deposited on our construction platform. And one of the most important aspects will be the choice of it, always depending on the type of material to be used, and now we will see why.

Before starting and if you like our articles, don’t forget to add us to our social networks (Facebook, Twitter and Instagram), or visit us on our Telegram channel.

Nozzle: Basic features

Although the choice of our nozzle is an important point, since it will partly define the quality of our prints and the materials to be used, it is still a fairly simple process.

In principle it would be advisable to take into account 3 basic parameters. Although the price can also be something important to have in mind, we have not considered it a “decisive” factor to take into account.

Inexpensive nozzles can give excellent results too, as long as the manufacturing process (and its tolerances) are adequate and we do not find products of very low or doubtful quality.

Nozzle type

Since the 3D printer fever began, different types of nozzles and variations have seen the light, always depending on the model or manufacturer of the 3D printer. However, we could say that the main, or most popular, would be the following:

- Nozzles MK8: This type of nozzles is found in many chinese “low-cost” printers, such as the Creality Ender 3 or similar.

- Nozzles MK10: Like the MK8 nozzles, these are often used in the same range of low/medium cost printers. Note that the MK10 is an improvement/evolution of the Nozzle MK8.

- Nozzles V6: This type of nozzle could currently be considered the de facto standard.

- Nozzles Volcano: Another evolution of the previous one more focused on certain materials and machines destined to operate with high extrusion volumes and speed. Or simply with much more technical or exotic materials demanded by the application in question.

Nozzle diameter

Basically it is the diameter of the exit hole of the Nozzle where the completely melted filament is extracted and deposited on the printing platform or on the printed part itself.

There is a wide range of measures to suit the consumer. However, we could say that the most common are between 0.25mm in diameter and 1.2mm in diameter. This does not mean that there are no measures higher or lower than this range, they are simply more specific and less used.

At this point I would like to indicate that the accuracy or tolerance of the nozzle manufacturing is of vital importance, since in the filleting machine we will indicate its diameter and any variation will result in direct loss of quality, over extrusion and even jams ( in extreme cases).

Filament types

Another very important fact that must be taken into account is the material in which our Nozzle is manufactured.

As our component in question passes through the plastic, it is exposed to continuous wear that ends up enlarging its diameter and forcing us to replace it.

Filaments with wood, iron (magnetic), copper (conductive) or carbon fiber particles are abrasive and eventually wear out our nozzle. So you must choose the appropriate Nozzle for your print filaments.

Fabrication material

The manufacturing material of our nozzle will indicate the type of filaments to be used, their durability in the face of the abrasion process and, of course, its cost, since depending on the material it will be different.

Some of the materials that are normally used in the production and manufacture of nozzles for 3D printing are the following:

Brass

They are usually the most common and inexpensive, in addition to having good heat transfer characteristics. This means that it is highly efficient in transferring heat from the heater/fuser block to the filament.

It is usually the best option to start exploring the world of 3D printing before going to other more expensive options. However, brass is a soft material that can easily be damaged or worn by the abrasion of the filament, poor handling or time of use.

Stainless steel

Originally intended to produce food-related prints. They do not have any special benefit to highlight, they have a high cost, thermal conductivity characteristics worse than brass and they do not excessively improve their wear with the use of abrasive materials.

Copper-Nickel-plated

Nickel-plated copper alloy nozzles have better thermal characteristics than brass ones. In addition, thanks to their characteristics, they are perfect for working on viscous materials such as PETG since they tend not to adhere to the nozzle, accumulating remains of filaments and leaving artifacts in our prints.

They have a intermediate cost and in addition to working sensationally with viscous materials, this same characteristic makes them the most suitable for working with small prints or with a lot of detail using nozzles with diameters less than 0.4mm.

Hardened steel

Hardened steel nozzles are one of our favorites because they are most versatile. Thanks to their hardness and durability they allow us to work with more technical filaments such as carbon fiber, metal, wood or other similar ones.

Hardened steel nozzles on the other hand do not have as good heat transfer as others, so we will have to increase the temperature a bit. This is something that will make us have to refine our printing profile a bit more, since they tend to create more threads or Stringing in our impressions.

Ruby

Originally focused on printing technical materials that require high temperatures. Obviously, as you can imagine, they have a high cost and are quite fragile. They are certainly a very specific choice, and perhaps unnecessary on most desktop (hobby) 3D printers.

Tungsten

We could say that they are one of the perfect nozzles given their durability and excellent thermal conductivity characteristics. On the other hand, its cost is quite high, so I would only recommend it for professional applications.

You can find it in high-performance extruders such as DyzeXtruder Pro: Analysis of a high-performance extruder for professional environments

Titanium

With the rise of barrels of this material, which for that component is a very suitable material, several manufacturers have launched Nozzles or mouthpieces of this material.

However, it should be noted that titanium has horrible thermal conductivity, so it would be a poor choice for a part as vital as our nozzles.

Coated

Some manufacturers of nozzles for 3D printing have in their catalog nozzles with the aforementioned materials but with a specific coating to improve their thermal characteristics and durability.

Normally this type of nozzles usually provide, in addition to the improvements mentioned, a lower rate of adhesion of the filament to the nozzle.

This option is quite interesting, especially if we often work with more viscous filaments such as PETG. One of those that in our point of view could be the best nozzle is the E3D’s Nozzle X, and probably the most balanced in all its features.

Nozzle cost

Of course, a very important aspect that we must not forget among all the characteristics of the nozzle or mouthpiece is its cost or price.

And when we talk about cost, we are not only referring to the price of the material, but also to costs derived from time/repairs and plastic from failed prints.

Using a material that is not suitable for our filament/machine can affect the quality of our prints, so in addition to selecting the most suitable material it is important that the durability and quality are correct.

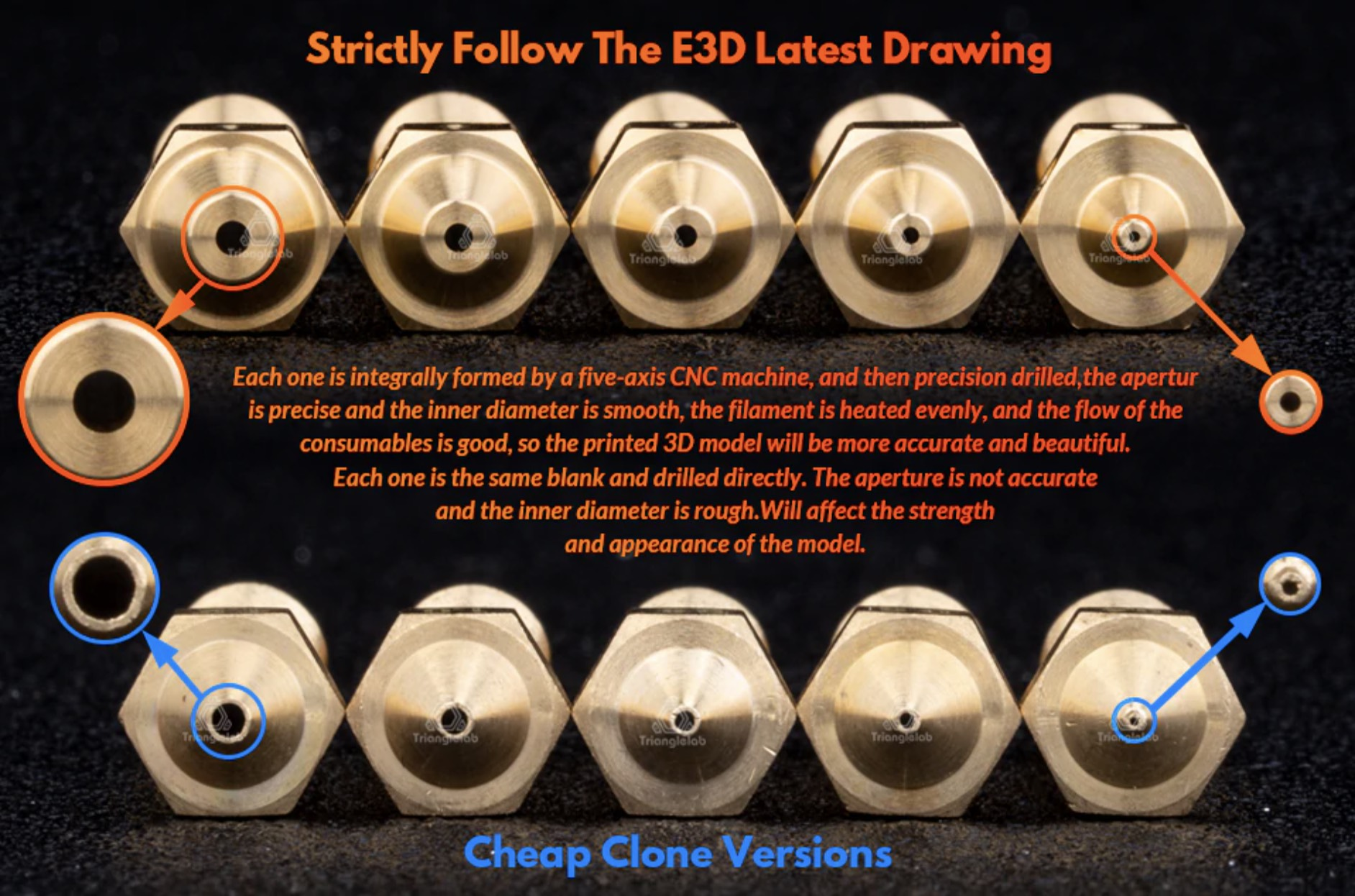

In the image above you can see the difference between a Chinese manufacturer (clones) and quality Nozzles, it jumps at a glance.

Extrusion diameter

The extrusion diameter of our nozzle will determine the use, quality and speed of our prints.

An interesting study by Prusa shows that only 22% of 3D printer users have tested different diameters of nozzle. And it is surprising, since changing the diameter of our nozzle gives us greater speed or precision when facing our pieces.

Broadly speaking, our suggestions as a reference could be these:

- Large impressions: Where we would use nozzles from 0.8mm to 1mm in diameter, hardened or coated steel such as the E3D Nozzle X

- Functional/normal impressions: In this case we would opt for the use of nozzles from 0.4mm to 0.6mm in diameter and equally hardened or coated steel.

- Small impressions/detail: We would use copper-nickel-plated 0.25mm to 0.35mm nozzles, and if possible coated to avoid that the filament is adhered to the nozzle.

How does diameter affect our print profile?

When changing the diameter of our nozzle we have to bear in mind that it will require modifying certain parameters of our printing profiles. Basically they would be these:

- Extrusion width: Obviously if we change the diameter of our nozzle, the extrusion width will be affected.

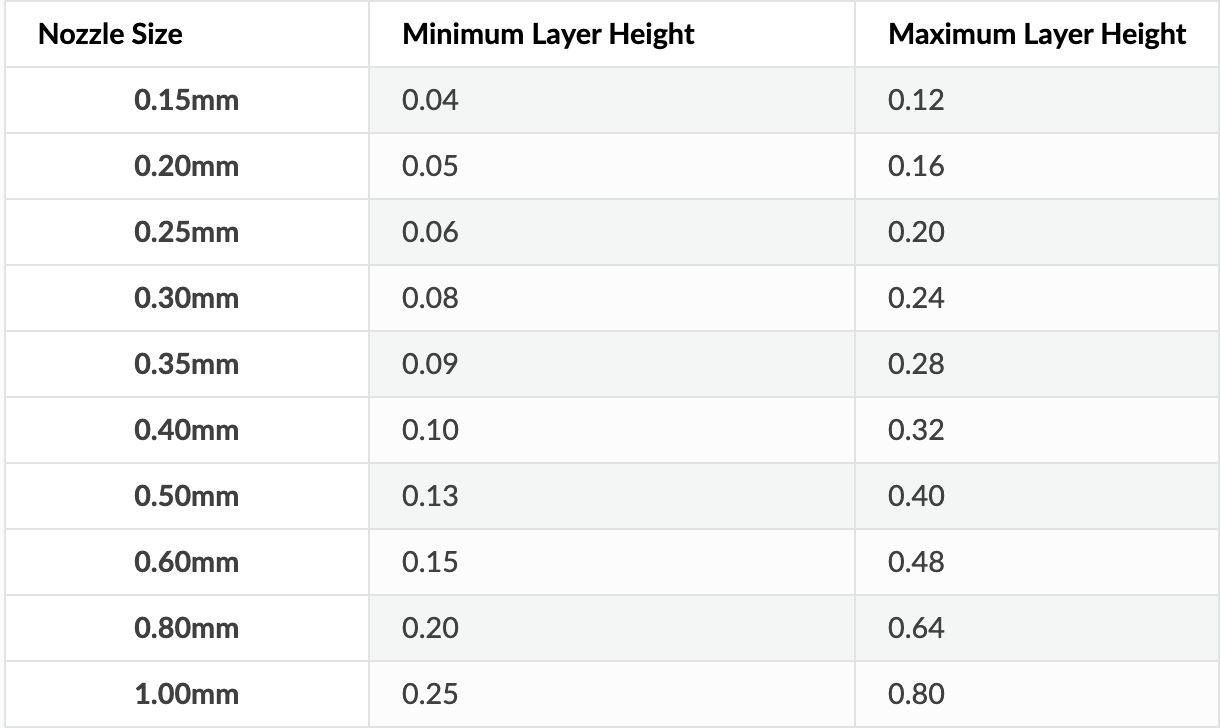

- Layer height: Another factor that is affected by the change in diameter of our nozzle is the layer height, which we always recommend following 3 basic parameters:

- Minimum layer height: As a rule In general we will apply 25% of the diameter of the nozzle

- Maximum layer height: In this case we will use 80% of the diameter of the nozzle

- Intermediate measurements between min. and max. layer height: To calculate these intermediate measurements we will try to use the “magic” multipliers using multiples of 0.04mm to eventually make them coincide with the resolution of our engines

- Flow: Whenever we change the diameter of our nozzle, we must perform a flow test to adjust this important change in our extrusion system.

- Printing speed: With the change in diameter and the parameters it affects, the printing speed will be affected.

Since there are a multitude of parameters to take into account, there is no “magic” formula to follow when adjusting the speeds.

However, in some laminators like PrusaSlicer/SuperSlicer we can use MVS or maximum extrusion speed, which will leave it up to the laminator to use the most appropriate speed in each case.

Conclusions

To get the most out of our printers, the use and choice of the nozzle is a fundamental part.

We must bear in mind that a Nozzle is a relatively “inexpensive component, so investing in more quality will result in considerable savings in the medium/long term.

Both in time (failed prints), as well as money (discarded filament in failed prints or more nozzle replacements).

For use in functional pieces we will normally use 0.4/0.6mm diameters, and well adjusted the printing profile we will not see differences between both at the same layer height and yes a saving of printing time, in addition to allowing us to work with greater heights of layer.

On many occasions we tend to print at very small layer heights that in many cases do not provide improvements / detail if we do not change the diameter of our nozzle and add unnecessary printing time.

As always, we hope that the article has been to your liking. You can read other interesting articles on our blog:

- Elegoo Mars 2 Pro: Review of a great resin printer for home use

- BTT Octopus: Analysis and Setup Guide with Marlin and Klipper

- FYSETC S6: Complete guide to this excellent electronic board for our 3D printers

- BTT SKR 2: How to detect and repair the failure of the first revisions (REV A)

- Elegoo Jupiter 6K: A new flagship arrives on the Crowdfunding platform Kickstarter

- Monoprice Mini Delta v2: The perfect choice to get started in 3D printing

- 3D printed Simpsons TV that plays the episodes randomly

- BigTreeTech SKR 2: Guide and setup of this new electronics

- Complete guide Fysetc Spider: A real “beast” for our 3D printers

- New Marlin Builder v2.0 update (+220 firmwares available v2.0.9.1)

Déjanos un comentario